Snooping inside a classic car factory

Why robots will never replace humans at British Motor Heritage

British Motor Heritage is the kind of place that makes you question what obsolescence really means. I had the privilege of a tour around their Witney-based factory for Practical Classics magazine a few months back. It turned out to be a treasure trove for fans of British classics – especially Minis, MGs, Jaguar E-types and various Triumphs.

I learned far more than would fit in the mag (such is the nature of magazine publishing these days… grrr, etc.) so to help make up for it, I thought I’d share a few snippets here. If you’re into old machines and the skills required to use and maintain them, this is for you.

The amount of knowledge and skills that have built up within this business is deeply impressive. BMH uses the original presses and tooling to create hundreds of body panels for British classics, including complete shells for Minis, MGBs and Midgets.

No robots here. The cold mechanisation of the production line is useless without the judgement and skill of the men (and they are all men, as far as I could see) who make it work.

The presses that initially form the panels from sheet steel are operated in Leamington Spa by Taylor Pressform. Then the pressed panels are brought to BMH's Whitney headquarters for trimming, adjustment and assembly, using jigs that have been rescued from the original assembly lines. Some are fixed at awkward-looking angles, almost giving the impression of a bizarre Escher invention, but everything is intentional; each jig is designed to receive one particular piece of bodywork for one particular part of the process.

Red jigs are for the MGB. Yellow means Midget. Blue means Mini.

Given the age of these tools, many are in need of preservation and sometimes refurbishment, especially the ones that have to live outside. It’s an ongoing chore that BMH is committed to – although unused tools are occasionally scrapped, after consultation with specialists. (The tooling to make Dolomite valances is a recent casualty.) Each scrappage is a potentially controversial decision, and not one that is made lightly.

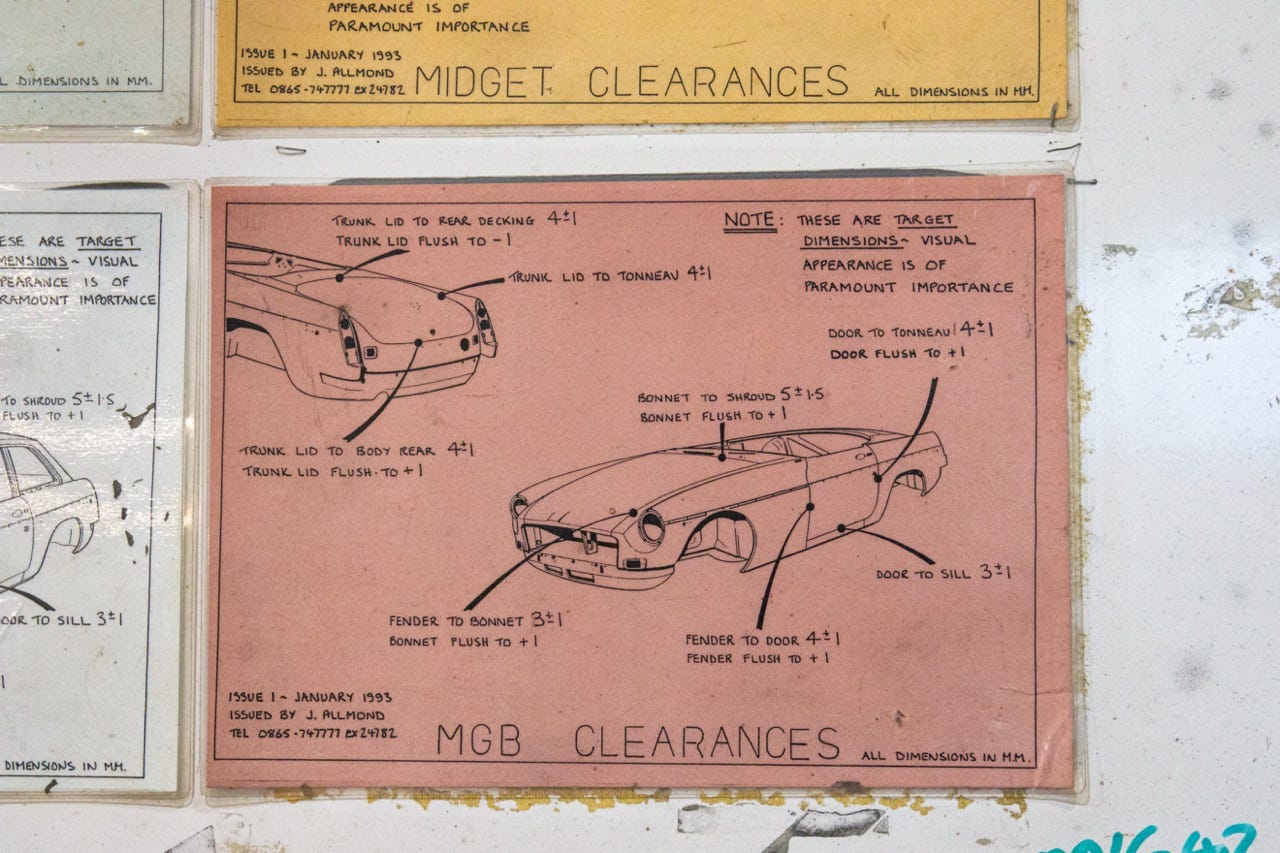

I love the notices in the assembly booths warning that pre-determined measurements should be taken too seriously: 'Note: these are target dimensions - visual appearance is of paramount importance.' These are all original notices taken from the cars’ original assembly lines, each one immaculately drawn and including the month and year of its creation.

Each notice reminds us that building cars like these was, and still is, a craft – not merely an assembly process. Of course, if all the measurements are spot on, it should also look right too, but ultimately the high tolerances within the old tooling (which itself wears out over time) make it impossible for each panel to be precisely identical. Human judgement therefore has to be part of the process.

If you’ve ever restored an old car yourself, you’ll know that a good deal of slicing and thumping and bending and jiggery-pokery is needed to make panels line up correctly – but there’s something comforting in knowing that the blokes at the factory have to do the same.

Spreading its wing mirrors

These days BMH owns a few subsidiary businesses including Tex Automotive, an old British brand making little ancillary items like mirrors and wiper arms for classic cars, with its production area now housed upstairs in the same building. I never thought I'd get excited about something as trivial as a wiper arm, but quality can be found in unexpected places. When you examine the old machine that rivets them together and see how it's done (a heavy contraption the size of a toaster is dedicated to the sole purpose of applying just one rivet) you start to appreciate mundane components in a new way.

There’s an undercurrent of modernisation happening here too. A recent £110,000 investment in 460 rooftop solar panels had knocked 60,000 tonnes off BMH’s annual carbon footprint. Together with an upgrade to LED lighting, that helped shield the businesses from the massive electricity bills that hit the rest of the industry post-Covid. ‘We’d be a lot worse off if we hadn’t done that,’ Graham told me.

Trying to future-proof a business that's so heavily reliant on skills and tools from a different age of manufacturing can't be easy, but BMH seems to be dedicated to pulling it off.

If you’d like your own guided tour of British Motor Heritage, they are available by special request.

Writing about classic cars (and Land Rovers) has been part of my day job for years, but it’s not something I’ve really brought to Substack – until this post. If it’s something you’d like to see more of, let me know. I’m still figuring out what I’m doing here, so any nudges are gratefully received.